How does a Pogo pin conduct electricity?

A Pogo pin is a common metal item commonly used in electronic devices as a wire connection. It is slender and flexible, so it is widely used in a variety of connectors, switches and terminals. The conductive properties of

Pogo pin mainly depend on the conductive properties of its metal material. Below we will discuss the conduction principle and process of Pogo pin in detail.

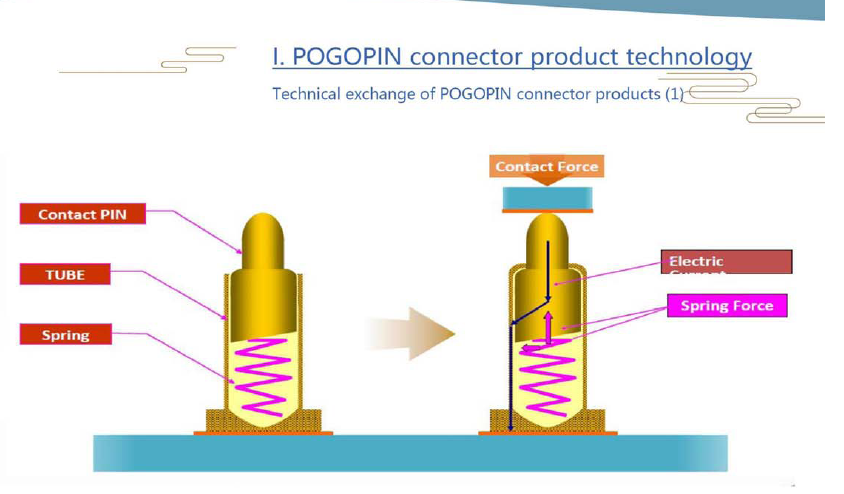

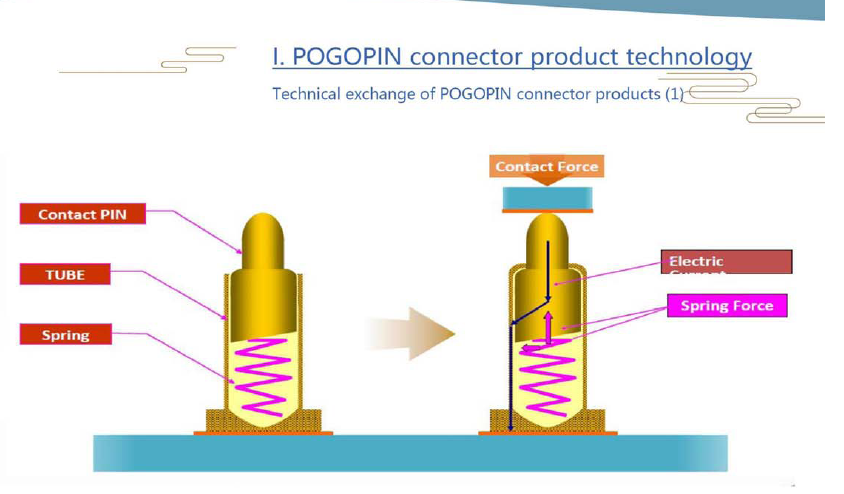

First, we need to understand the construction of a Pogo pin. The Pogo pin consists of two main parts: the needle and the needle tube. Needles are slender metal rods, usually made of conductive materials such as copper, nickel, or stainless steel. The needle tube is a flexible metal tube that wraps around the outside of the needle, providing protection and ensuring the flexibility of the Pogo pin.

When the current is passed through the Pogo pin, the first part of the needle comes into contact with the current. Because the needle is made of conductive material, it is able to transfer an electric current from one side to the other. Specifically, when an electric current is applied externally to one end of a Pogo pin, these currents flow through the needle from one end to the other. In this process, electricity flows through the material of the needle, using free electrons in the metal.

Let's explore this process in more depth. When an electric current is applied to the Pogo pin, free electrons in the metal material begin to flow under the action of an electric field. These electrons move in the direction of the electric field, creating an electric current. Due to the excellent electrical conductivity of the metal, the current can flow smoothly inside the Pogo pin, thus achieving the transmission of electrical signals.

It is worth noting that the electrical conductivity of the Pogo pin depends not only on the electrical conductivity of its metal material, but also on its contact area. Due to the elongated and curved shape of the Pogo pin, a certain contact area is formed when it comes into contact with other conductors. The size of this contact area directly affects the resistance of the current passing through the Pogo pin. The larger the contact area, the smaller the resistance; The smaller the contact area, the greater the resistance.

In addition, the surface state of Pogo pin also has a certain influence on its electrical conductivity. If there is an oxide layer, contamination layer or oxide film on the surface of the Pogo pin, these factors will hinder the flow of current and increase resistance. Therefore, before using Pogo pin, it is usually necessary to carry out some surface treatment, such as cleaning and polishing, to ensure that its surface is in good condition, reduce resistance, and improve electrical conductivity.

In short,

Pogo pins conduct electricity by taking advantage of the conductive properties of the metal and controlling the contact area and surface state. Its slender shape and good flexibility make it ideal for connecting lines in electronic devices. By understanding the conduction principle and process of

cnomax Pogo pin, we can better understand its application and role in electronic devices.