How many Voltage Rating of Pogo Pins?

Pogo pins, or spring-loaded connectors, are essential components used in a wide variety of electronic applications where temporary electrical connections are needed. These small, reliable connectors are commonly found in testing systems, circuit boards, connectors for mobile devices, and even in automotive and industrial electronics. While much attention is given to the current carrying capacity of

pogo pin, understanding their voltage rating is just as important when selecting the right pogo pin for a specific application.

The voltage rating of a pogo pin is critical in ensuring that the pin can safely handle the electrical potential difference without breaking down the insulation or causing arcing, short-circuiting, or other failures. This article will provide a detailed discussion on the voltage rating of pogo pins, the factors that influence this rating, typical voltage ratings for different types of pogo pins, and best practices for selecting the right pogo pin for high-voltage applications.

1. What is Voltage Rating?

The voltage rating of a pogo pin refers to the maximum electrical potential difference (voltage) that can safely be applied across the pin without causing breakdown or failure of the pin’s components. This rating depends on several factors, such as the materials used, the design of the pin, the physical distance between the contact elements, and the environmental conditions.

In simple terms, the voltage rating indicates how much voltage can be applied across the pogo pin without risk of electrical failure. Exceeding this voltage rating can lead to a phenomenon known as electrical arcing, which can cause permanent damage to the pin or even create short circuits that may harm the connected electronic circuits.

2. Factors Influencing Voltage Rating of Pogo Pins

Several factors determine the voltage rating of a pogo pin. These factors must be carefully considered in any design to ensure that the pogo pin can reliably handle the voltage without failure.

2.1 Contact Material

The material used for the contact surfaces of the pogo pin is one of the most important factors affecting its voltage rating. Materials that exhibit better electrical conductivity tend to perform better in high-voltage applications. The most common materials used for pogo pin contacts include:

Gold: Gold is an excellent conductor of electricity and has superior resistance to oxidation. It is commonly used for high-reliability applications, such as high-speed data transfer or high-voltage environments. Gold-plated pogo pins typically have high voltage ratings and excellent performance over time.

Silver: Silver is another excellent conductor of electricity and is sometimes used for high-voltage pogo pins, especially in industrial applications. Silver-plated contacts are known for their low electrical resistance, but they may be prone to oxidation and tarnishing if not properly coated or treated.

Copper: Copper is commonly used in the pin body for its excellent conductivity. However, pure copper may require a protective coating (e.g., nickel or gold plating) to ensure long-term reliability in high-voltage environments.

Nickel: Nickel is often used as a coating for contacts and is selected for its durability and resistance to corrosion. Nickel-plated pogo pins are suitable for low to medium voltage applications.

The material choice affects the ability of the pogo pin to withstand electrical stress, minimize voltage breakdown, and prevent arcing. Gold and silver are preferred for high-voltage, high-reliability applications, whereas nickel and copper are more commonly used for lower voltage applications.

2.2 Contact Pressure and Contact Area

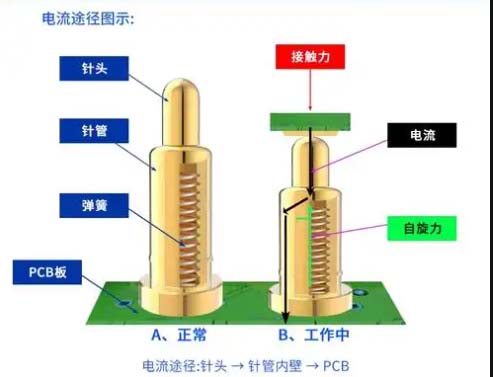

The pressure with which the pogo pin’s internal spring mechanism forces the contact elements together is another factor that influences the voltage rating. A tighter contact force generally results in a more stable electrical connection, reducing the risk of arcing or breakdown at higher voltages.

Increased Contact Area: A larger contact area can help distribute the electrical potential more evenly across the pin, reducing the likelihood of localized overheating or electrical breakdown. The increased contact area may allow the pogo pin to handle higher voltages because the potential difference is spread over a greater area.

Contact Force: If the contact force is too low, the connection may not be firm enough, leading to poor electrical contact and potentially allowing for arcing or sparking at high voltage. Conversely, too much pressure may cause mechanical wear on the contact surfaces, leading to eventual failure.

The correct balance of contact area and pressure is necessary for ensuring that the pogo pin can handle the maximum voltage without failure.

2.3 Dielectric Properties of the Housing and Insulation

The dielectric strength of the material used for the housing and insulation of the pogo pin is also a crucial factor in determining the voltage rating. Dielectric strength refers to the ability of an insulating material to resist electrical breakdown when exposed to high voltage.

Housing Materials: The material surrounding the pogo pin’s electrical contacts serves as an insulator that separates the conducting elements from each other and from external parts of the device. Materials such as plastic, ceramics, or composite polymers are commonly used as the insulating housing material. The dielectric strength of these materials will determine the maximum voltage that can be applied across the pogo pin before electrical breakdown occurs.

Insulation Between Contacts: The internal insulation, such as the gap between the pogo pin and its housing, plays a significant role in preventing short circuits or arcing between the pin’s contacts. The distance between the conductive elements of the pogo pin and the insulating material will determine the maximum voltage it can handle. The larger the separation between the conductive parts, the higher the voltage the pin can carry.

The quality and properties of the insulating material are critical when designing a pogo pin for high-voltage applications. High-quality dielectric materials provide better insulation, allowing the pin to carry higher voltage without breakdown.

2.4 Environmental Factors

Environmental conditions, including temperature, humidity, and the presence of corrosive substances, can affect the voltage rating of a pogo pin. For example:

Temperature: At higher temperatures, materials may become more susceptible to electrical breakdown. The voltage rating of a pogo pin typically decreases with an increase in temperature. In high-temperature environments, additional considerations must be made to ensure the pogo pin does not fail due to overheating. For instance, selecting materials with higher thermal stability or using proper heat dissipation methods could mitigate these issues.

Humidity: Moisture and humidity can lead to corrosion or short circuits within pogo pins, especially if the insulating housing or contact tips are exposed to prolonged moisture. In humid environments, gold-plated or silver-plated contacts are preferred due to their excellent corrosion resistance.

Contaminants and Pollution: Dust, dirt, or other contaminants in the environment can affect the performance of a pogo pin and reduce its voltage rating. Contaminants can create resistive paths that lead to voltage breakdown or arcing. For this reason, special coatings or sealed housings may be required in environments with high levels of contaminants.

2.5 Design of the Pogo Pin

The overall design of the pogo pin, including its length, diameter, and contact configuration, also plays a role in determining its voltage rating. Longer pins or pins with a greater gap between the contacts may be better suited to higher voltage applications because they provide a larger path for the electrical potential to travel, reducing the likelihood of arcing.

Additionally, the spring mechanism that pushes the pin into contact with the target pad or socket must be robust enough to ensure a consistent connection under varying mechanical stress. A poorly designed spring could result in insufficient pressure, leading to unstable contacts and an inability to handle high voltage.

3. Typical Voltage Ratings of Pogo Pins

Pogo pins are available in a variety of voltage ratings depending on their intended use and design. Here are some typical voltage ratings for different types of pogo pins:

3.1 Standard Pogo Pins

For most standard, low-to-medium current applications, such as testing and prototyping, typical voltage ratings range from 50V to 300V. These pins are often used in circuits with relatively low voltage levels, such as USB connectors, PCBs, or mobile devices.

Low Voltage Pogo Pins: Typically rated for 50V to 100V, these are commonly used in consumer electronics or internal circuit connections where voltage is relatively low.

3.2 Medium Voltage Pogo Pins

For medium voltage applications, such as certain industrial or automotive testing environments, pogo pins may be rated to handle voltages from 300V to 500V. These are typically used for testing purposes, such as in battery testing, automotive electrical systems, or industrial sensors.

3.3 High Voltage Pogo Pins

High voltage pogo pins are designed for specialized applications where higher voltages are involved. These pins can handle voltages ranging from 500V to 1000V or even higher, depending on their design and material specifications. High voltage pogo pins are often used in testing equipment for high-voltage electronics, telecommunications equipment, and industrial power systems.

High Voltage Pogo Pins: These may be rated for 1000V or more, with special coatings or insulations designed to withstand the electrical stresses of high voltage.

4. Best Practices for High-Voltage Pogo Pin Selection

When selecting a pogo pin for high-voltage applications, it is crucial to consider the following best practices:

1. Choose Proper Contact Materials: For high-voltage applications, gold-plated or silver-plated contacts are preferred due to their low electrical resistance and superior oxidation resistance.

2. Ensure Adequate Insulation: Choose pogo pins with high-quality insulation that is rated for the expected voltage, ensuring that the materials used for the housing and internal components have a high dielectric strength.

3. Account for Environmental Conditions: Consider the temperature, humidity, and potential contaminants in the operating environment. If necessary, choose sealed or coated pogo pins for added protection.

4.Test for Voltage Breakdown: Before deploying high-voltage pogo pins in a system, perform electrical breakdown testing to verify the pin’s voltage tolerance and ensure reliability under operational conditions.

The voltage rating of a pogo pin is a critical factor in ensuring the safety and reliability of the connector in high-voltage applications. It is influenced by several factors, including the contact material, insulation, contact pressure, and environmental conditions. By understanding these factors and carefully selecting pogo pins based on their voltage rating, designers and engineers can ensure that their devices perform reliably without risk of electrical failure. Whether working with low-voltage consumer devices or high-voltage industrial applications, selecting the right pogo pin for the job is essential for long-term reliability and performance.