How many Maximum Current Capacity of Pogo Pins?

Pogo pins, or spring-loaded connectors, are crucial components in a wide variety of electronic devices and applications. These small yet versatile connectors are designed to provide a temporary electrical connection between two surfaces, such as circuit boards, testing pads, or other conductive materials. Given their widespread use in many industries, from consumer electronics to automotive, telecommunications, and even medical devices, understanding the current carrying capacity of pogo pins is vital for their proper application and ensuring reliable performance.

The current carrying capacity of a pogo pin depends on various factors, including the materials used, the design of the pin, the contact surface area, the environmental conditions, and the physical constraints of the pin itself. In this detailed article, we will explore the factors that influence the current carrying capacity of

Pogo pin, the typical values you can expect, the limitations, and how to choose the right pogo pin for specific current applications.

1. Basic Principles of Pogo Pin Design

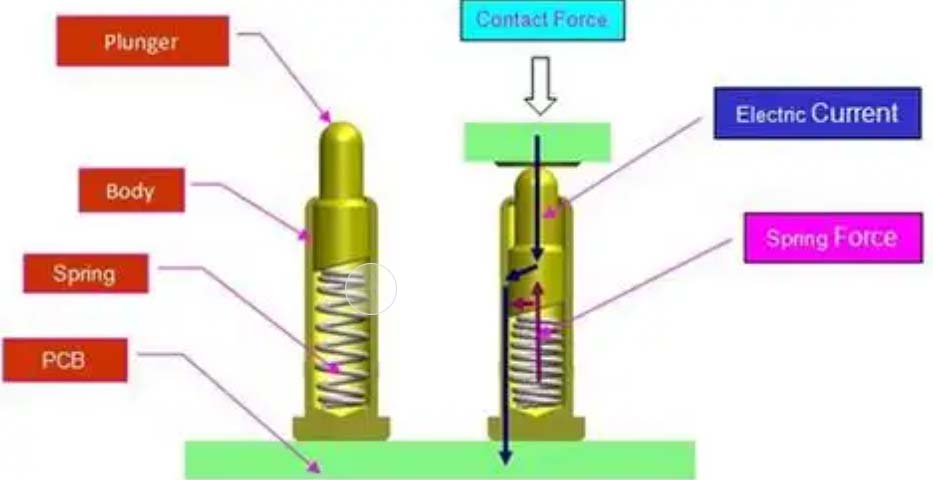

Before diving into the specifics of current capacity, it is important to understand the basic design elements of a pogo pin. A pogo pin consists of several key components:

Pin or Contact Element: The actual conductive part of the pogo pin that makes contact with the corresponding pad or socket.

Spring Mechanism: The spring inside the pogo pin allows it to maintain contact pressure and facilitate the engagement of the connector with the surface it touches.

Housing: The body or casing of the pogo pin that holds the pin and spring in place.

Contact Tip: The very end of the pin that physically touches the surface, which could be gold-plated, nickel-plated, or made of other conductive materials for improved electrical performance and resistance to wear.

The current carrying capacity of the pogo pin is directly related to the size and material of these components. The electrical contact resistance between the pin and the pad, the contact area, and the mechanical properties of the pin all influence its ability to carry current.

2. Key Factors Influencing Current Capacity

2.1 Material Properties

The material used in the construction of a pogo pin is one of the most significant factors in determining its current carrying capacity. Several materials are commonly used in pogo pins, including brass, copper, stainless steel, and various alloys, and each material has distinct properties that affect its electrical and thermal performance.

Copper: Copper is one of the best materials for electrical conductivity, and it is often used in high-performance pogo pins. Copper has low electrical resistance, which allows it to carry higher currents without excessive heat buildup. However, copper is relatively soft and may be prone to mechanical wear over time.

Brass: Brass is commonly used for both the pin and housing in standard pogo pin designs. It has good electrical conductivity and decent corrosion resistance, though not as high as copper. Brass is more durable than copper and is often used in applications that do not require the highest possible conductivity but still need good mechanical properties.

Stainless Steel: Stainless steel is often used for the housing or spring mechanism in pogo pins. While it does not have as high electrical conductivity as copper or brass, it provides excellent mechanical strength, corrosion resistance, and durability, making it suitable for harsh environments. Stainless steel is less conductive, which can limit the maximum current that can safely pass through a pin made from this material.

In high-current applications, it is often necessary to use special coatings, such as gold plating or silver plating, on the contact tips. These materials not only improve the electrical conductivity but also provide resistance to oxidation and wear, ensuring a reliable connection over time.

2.2 Contact Surface Area

The contact surface area is another critical factor influencing the current carrying capacity of pogo pins. The larger the contact area between the pogo pin and the corresponding pad or socket, the more current the pin can carry. This is because the current is spread over a larger area, reducing the heat density and preventing overheating.

In practice, the size of the contact tip or the diameter of the pogo pin will influence the overall current rating. A larger tip or a pin with a larger contact area will typically have a higher current carrying capacity, as it can handle more power without excessive heat buildup. However, it’s important to balance the size of the contact area with the available space and the physical design constraints of the device.

2.3 Electrical Contact Resistance

Electrical contact resistance is the resistance encountered by the electrical current as it passes through the interface between the pogo pin and the surface it connects to. This resistance is affected by factors such as the material of the contact, the pressure applied by the spring, and the cleanliness of the contact surfaces. High contact resistance leads to power dissipation in the form of heat, which can limit the amount of current that can safely flow through the pin.

Low Contact Resistance: Pogo pins with low contact resistance allow higher currents to flow with less heat buildup. This can be achieved by using high-conductivity materials like gold or silver for the contact tips, and by ensuring that the spring mechanism applies enough pressure to create a tight connection.

Surface Coatings: The use of coatings, such as gold, silver, or nickel plating, can further reduce contact resistance. Gold is particularly effective in reducing contact resistance because of its excellent conductivity and resistance to oxidation, making it ideal for high-reliability applications where current flow is critical.

2.4 Thermal Considerations

As current flows through a pogo pin, it generates heat due to the resistance of the contact interface and the material. This heat must be dissipated to avoid overheating, which could damage the pin, affect the electrical connection, or even cause a short circuit.

The temperature rise of the pin is a crucial factor in determining the maximum current it can safely carry. If the current is too high, the temperature rise can exceed the thermal limits of the materials used in the pin, leading to failure. The design of the pogo pin, including factors such as the material’s thermal conductivity, the contact pressure, and the size of the pin, will determine how effectively heat is dissipated.

Thermal Management: To manage heat dissipation, pogo pins are often used in conjunction with heat sinks or thermal management systems in high-power applications.

Current Derating: In some cases, manufacturers may specify a derating factor for high-current applications, which means that the maximum current must be reduced based on the operating temperature or environmental conditions.

2.5 Spring Force and Mechanical Stress

The spring inside the pogo pin ensures that the pin remains in contact with the target pad, providing the necessary force to maintain the electrical connection. However, the spring must also be designed to withstand the mechanical stress that comes with carrying higher currents.

Spring Force: The spring force must be balanced to ensure a tight connection while avoiding damage to the contact surfaces. Excessive force could lead to wear and tear, while too little force could result in unreliable connections.

Material Fatigue: Springs made from materials like stainless steel or music wire must also be designed to resist fatigue over many cycles of compression and decompression. If the spring wears out too quickly, the mechanical integrity of the pogo pin could degrade, impacting its current carrying capacity.

3. Typical Current Carrying Capacities

The current carrying capacity of a pogo pin is highly dependent on its design and the materials used, but there are general ranges for common types of pogo pins.

Standard Pogo Pins: In general, a standard pogo pin made from brass or copper and with a typical contact size (e.g., 1-2 mm diameter) can carry between 0.5 to 3 amps of current reliably. These types of pogo pins are used in low- to medium-power applications, such as testing, mobile devices, and PCBs.

High-Current Pogo Pins: For more demanding applications, such as high-power testing, automotive electronics, or industrial equipment, special high-current pogo pins can be designed. These pins may be larger in size, with increased contact areas, and use materials like gold or silver for the contact tip. High-current pogo pins can typically handle currents of 5 to 10 amps, or even higher in some specialized designs.

Heavy-Duty Pogo Pins: Heavy-duty pogo pins, often used in high-power circuits or battery-powered systems, can be designed to handle currents of 20 amps or more. These pins usually feature larger contact surfaces, thicker bodies, and specialized materials like silver-plated copper or brass for improved conductivity.

4. Choosing the Right Pogo Pin for High-Current Applications

When selecting a pogo pin for a high-current application, there are several factors to consider:

1. Current Rating: Ensure that the maximum current rating of the pogo pin matches or exceeds the expected current in the application.

2. Thermal Management: Consider the potential heat buildup and whether additional cooling mechanisms, like heat sinks, are needed.

3. Material Selection: Choose materials with high electrical conductivity and low contact resistance, such as gold-plated or silver-plated tips.

4. Size and Contact Area: Larger contact areas typically allow higher currents to flow with less heat buildup. Select a pin with an appropriate size for the current requirements.

5. Mechanical Durability: Ensure that the pin’s spring mechanism can withstand the mechanical stress over long periods, particularly in applications with frequent insertions and extractions.

The current carrying capacity of a pogo pin is determined by a combination of factors, including the materials used for the pin, spring, and housing, the contact surface area, the electrical contact resistance, and the thermal dissipation capabilities. Standard pogo pins can carry currents in the range of 0.5 to 3 amps, while high-current versions can handle 5 to 10 amps or more