Are pogo pins waterproof ? How to design ?

Pogo pins, also known as spring-loaded connectors, are widely used in modern electronics for their compact design, durability, and reliable electrical connectivity. One critical question that arises in their application is whether they are waterproof. The answer depends on the design, materials, and engineering specifications of the pogo pin in question. Below, we explore the waterproof capabilities of pogo pins in detail, supported by technical insights and real-world applications.

1. Understanding Pogo Pin Construction and Waterproofing Challenges

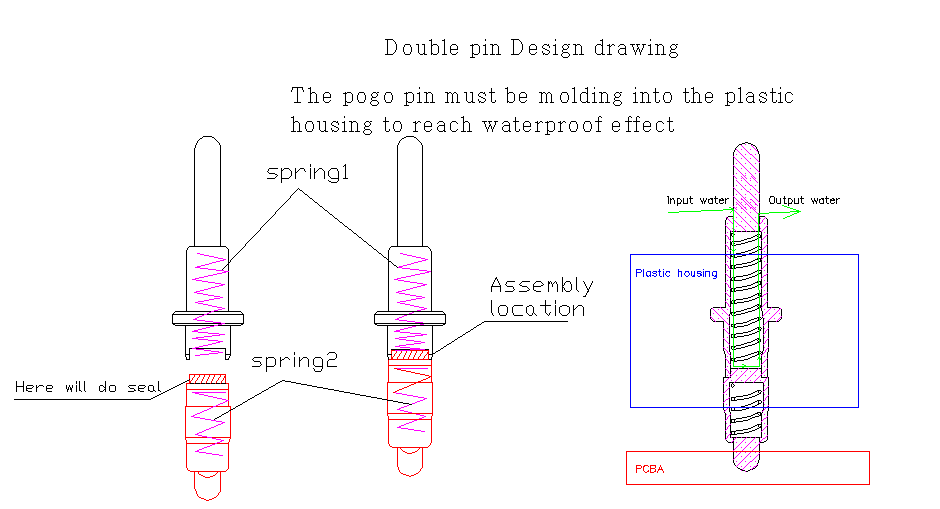

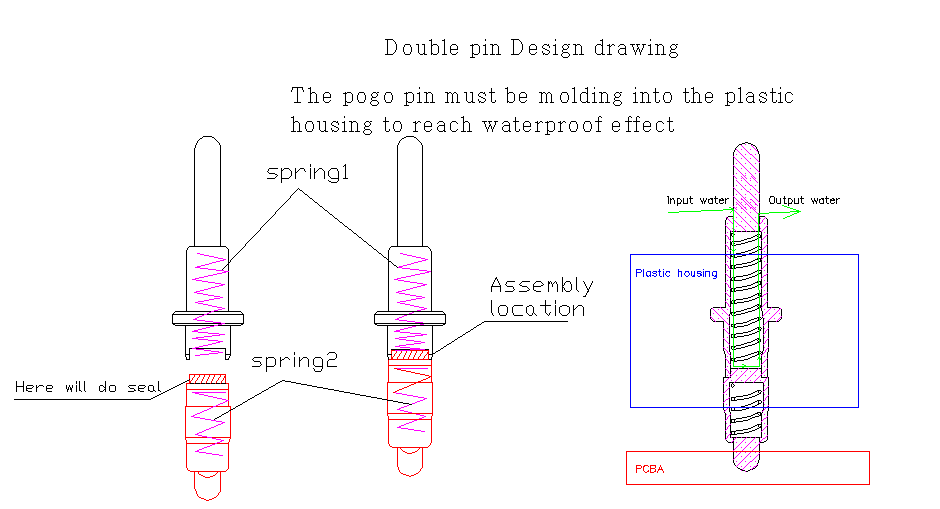

Pogo pins consist of three primary components: a plunger (needle), spring, and barrel (housing). These components work together to establish electrical contact through compression. However, their inherent design poses challenges for waterproofing:

- Exposed Contact Points: The plunger and barrel interface is typically exposed to the environment, making it susceptible to moisture ingress.

- Spring Vulnerability: The spring inside the barrel can corrode if exposed to water or humidity, degrading performance over time.

Despite these challenges, advancements in materials and engineering have enabled waterproof pogo pin designs. For instance, specialized seals, hydrophobic coatings, and precision manufacturing can mitigate water intrusion. For example, IPX8-rated pogo pins (submersible up to 1.5 meters for 30 minutes) are achievable through structural enhancements such as:

- O-Ring Seals: Integrated rubber or silicone seals around the plunger-barrel interface to block water.

- Potting or Encapsulation: Filling the connector housing with epoxy resin or other waterproof materials to protect internal components.

2. Waterproof Pogo Pin Applications

Waterproof pogo pins are increasingly critical in industries where exposure to moisture is inevitable. Key applications include:

a. Wearable Devices and Wireless Earbuds

Bluetooth earbuds and smartwatches often use

waterproof pogo pins for charging contacts. For example, magnetic charging cases for earbuds rely on pogo pins with IPX8 waterproofing to ensure reliable charging even in humid or wet environments. Dual Alliance Electronics highlights their development of waterproof pogo pins for wireless earbuds, emphasizing seamless charging via magnetic alignment and resistance to sweat or light rain.

b. Medical and Industrial Equipment

In medical devices or industrial sensors, waterproof pogo pins ensure functionality in sterilized or harsh environments. These connectors often incorporate corrosion-resistant coatings (e.g., gold or nickel plating) and sealed housings to meet stringent durability standards. For instance,

Cnomax Technology’s pogo pins are designed to withstand 48–120 hours of salt spray testing, making them suitable for medical and automotive applications.

c. Outdoor and Automotive Electronics

Devices like GPS trackers, dashcams, and outdoor lighting systems utilize waterproof pogo pins to endure rain, dust, and temperature fluctuations. The IP67/IP68 ratings are common in these applications, achieved through advanced sealing techniques and materials like stainless steel springs with anti-corrosion treatments.

3. Key Factors Enabling Waterproof Performance

Achieving waterproofing in pogo pins requires a combination of design innovations and material science:

a. Material Selection

- Corrosion-Resistant Metals: Plungers and barrels made from brass or stainless steel with gold/nickel plating reduce oxidation and enhance conductivity in wet conditions.

- Hydrophobic Coatings: Superhydrophobic surface treatments repel water, preventing short circuits and maintaining contact integrity.

b. Structural Design

- Magnetic Alignment: Magnets in connectors (e.g., MagSafe-style designs) ensure precise alignment, reducing wear on seals and improving waterproof reliability.

- Multi-Layered Sealing: Combining O-rings, gaskets, and molded plastic housings creates redundant barriers against moisture ingress. For example, Elecbee’s magnetic connectors use dual-circuit protection via magnetic alignment and structural seals to achieve IPX8 ratings.

c. Testing and Certification

Manufacturers rigorously test waterproof pogo pins under conditions simulating real-world exposure:

- Salt Spray Testing: Evaluates corrosion resistance over extended periods (e.g., 24–120 hours).

- Thermal Cycling: Tests performance across extreme temperatures (-40°C to 85°C) to ensure seals remain intact.

- IP Rating Validation: Certifications like IP67/IP68 confirm submersion and dust resistance.

4. Limitations and Trade-Offs

While waterproof pogo pins offer significant advantages, they are not universally applicable:

- Cost: Waterproofing adds complexity, increasing manufacturing costs by 20–30% compared to standard pogo pins.

- Size Constraints: Seals and coatings may limit miniaturization, making them less suitable for ultra-compact devices.

- Maintenance: Over time, seals can degrade, necessitating periodic inspections in critical applications.

5. Future Trends and Innovations

The demand for waterproof pogo pins is growing alongside the rise of IoT, wearables, and electric vehicles. Emerging trends include:

- Self-Healing Polymers: Materials that automatically repair minor seal damage to prolong lifespan.

- Nano-Coatings: Atomic-layer deposition (ALD) coatings for ultra-thin, durable waterproof layers.

- Modular Designs: Interchangeable pogo pin modules with varying IP ratings for flexible integration.

Conclusion

Pogo pins can indeed be waterproof, but their performance depends on targeted engineering solutions. Innovations in sealing, materials, and testing have enabled IPX8-rated connectors for applications ranging from consumer electronics to industrial systems. However, designers must balance waterproofing with cost, size, and durability requirements. As technology advances, we can expect even more robust and versatile waterproof pogo pins to emerge, further expanding their role in modern electronics.

For detailed technical specifications or custom solutions, refer to manufacturers like About

Pogo pin news