Influence analysis of Pogo Pin on other electronic components

The Pogo Pin, or spring pin connector, is a precision connector widely used in a variety of electronic products. It is mainly used for current conduction and data transmission, and plays an important role in charging, signal transmission and so on. However, Pogo Pin as an electronic component, its use may also have a certain impact on other electronic components. The following is a detailed analysis of the effect of Pogo pins on other electronic components:

The basic characteristics and working principle of

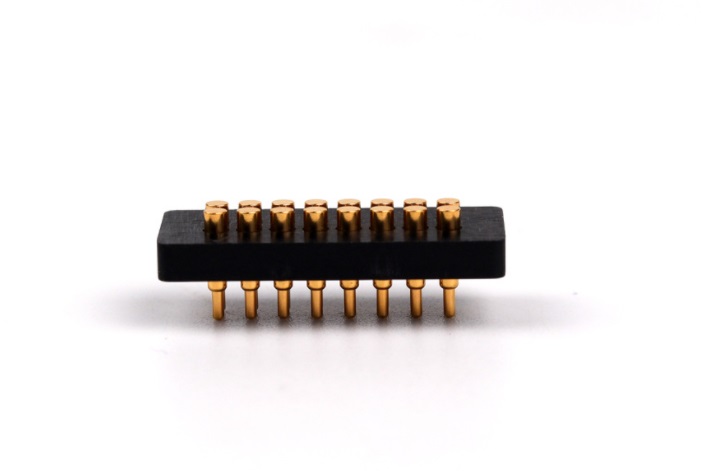

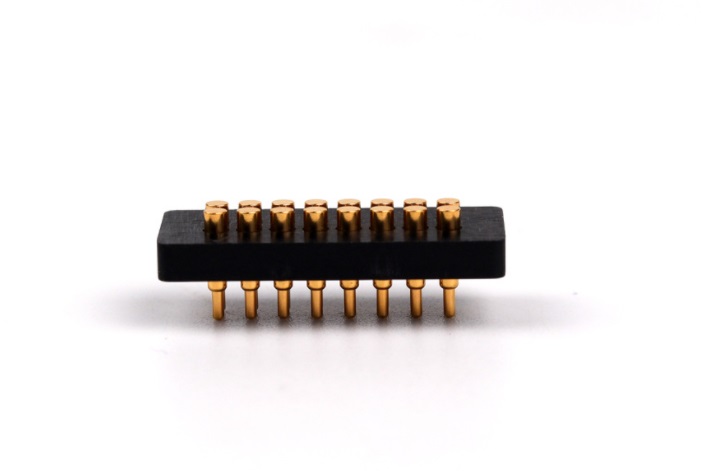

Pogo Pin

Pogo Pin is formed by three basic components of needle shaft, spring and needle tube after riveting and prepressing by precision instrument, and has a precise spring structure inside. When the Pogo Pin is in contact with other electronic components, the spring generates a certain contact force, ensuring a stable electrical connection. At the same time, the Pogo Pin also has the characteristics of elasticity and telescopic height adjustment, which can adapt to different contact environments and needs.

The potential impact of Pogo Pin on other electronic components

1. Electrical connection stability

Positive impact: The Pogo Pin provides a stable contact force through its spring construction, ensuring a stable and reliable electrical connection to other electronic components. This stable connection helps to reduce contact resistance and improve the accuracy and efficiency of signal transmission.

• Potential impact: If the Pogo Pin's spring strength is insufficient or there are problems such as dirt and oxidation on the contact surface, it may lead to poor contact, which will affect the stability of the electrical connection. This instability can cause problems such as signal transmission interruption, current fluctuations, and negatively affect the normal operation of other electronic components.

2. Electromagnetic Interference (EMI) and Radio Frequency Interference (RFI)

Potential impact: In high frequency signal transmission or applications with highly sensitive electronic components, Pogo pins can be a source of electromagnetic interference (EMI) or radio frequency interference (RFI). These disturbances may affect the normal operation of other electronic components, leading to performance degradation or failure.

• Countermeasures: In order to reduce the impact of electromagnetic interference and RF interference, the following measures can be taken: Select a Pogo Pin with shielding function; Optimize circuit layout and grounding design; Use filters, etc.

3. Thermal effect

• Potential impact: In the case of high current transmission or long working time, Pogo Pin may generate some heat. If the heat is not dissipated in time, it may cause its temperature to rise, which will affect its performance and life. At the same time, high temperatures may also have a thermal effect on other adjacent electronic components, resulting in performance degradation or damage.

• Countermeasures: In order to reduce the influence of thermal effect, Pogo Pin with good heat dissipation performance can be selected; Optimize circuit design and heat dissipation structure; Control the current size and working time.

4. Mechanical stress and vibration

Potential impact: In environments with high mechanical stress or vibration, Pogo pins may be impacted or vibrated, resulting in poor contact or damage. This damage will not only affect the performance of the Pogo Pin itself, but may also cause mechanical stress or vibration transmission to other adjacent electronic components, resulting in reduced performance or damage.

• Countermeasures: In order to reduce the impact of mechanical stress and vibration, Pogo Pin with seismic performance can be selected; Optimizing circuit layout and fixing method; Use cushioning materials, etc.

5. Chemical corrosion and oxidation

• Potential impact: In some harsh environments, such as moisture, corrosive gases, etc., Pogo Pin may be chemically corroded or oxidized. This corrosion or oxidation will cause problems such as increased roughness of the contact surface and increased contact resistance, which will affect the stability of the electrical connection and the normal operation of other electronic components.

• Countermeasures: In order to reduce the impact of chemical corrosion and oxidation, Pogo Pin with anti-corrosion properties can be selected; Optimize the use of environmental conditions; Regular inspection and maintenance.

Third, Pogo Pin and other electronic components work together

In practical applications, Pogo pins usually work together with other electronic components to achieve the functions of electronic products. In order to ensure the stability and reliability of the entire electronic system, it is necessary to consider the interaction between Pogo Pin and other electronic components.

1. Selection and matching: When selecting Pogo Pin, it is necessary to select the POGO PIN according to the specific application scenario and demand to ensure that its performance parameters (such as contact resistance, current carrying capacity, frequency response, etc.) match with other electronic components.

2. Layout and design: In the circuit layout and design, it is necessary to fully consider the position, direction, spacing and other factors of the Pogo Pin to avoid interference or conflict with other electronic components.

3. Testing and verification: In the process of electronic product development and production, adequate testing and verification work needs to be carried out to ensure that the cooperation between Pogo Pin and other electronic components is normal and reliable.

Iv. Conclusion

As an important electronic component, Pogo Pin plays an important role in the design and application of electronic products. However, its use may also have a certain impact on other electronic components. In order to ensure the stability and reliability of the entire electronic system, it is necessary to fully consider the interaction between Pogo Pin and other electronic components, and take appropriate measures to cope with and optimize. Through reasonable selection, layout, design and test verification, the advantages of Pogo Pin can be maximized and its potential impact on other electronic components can be reduced.