How to guarantee that the Pogo Pin will not be damaged during transportation?

When choosing the packaging of Pogo Pin, it is necessary to consider factors such as the characteristics of the product, transportation conditions and cost. The following are several recommended packaging methods and their application scenarios:

1.PE bag

• Application scenario: Suitable for small turning parts or a small number of

Pogo pins. PE bag is lightweight, good sealing, can effectively prevent dust and moisture intrusion, and the cost is low.

• Advantages: Economical price, easy to seal, suitable for short-term storage and small amounts of transport.

• Disadvantages: For large or heavy Pogo pins, PE bags may not provide adequate protection.

2. Blister box/tray

• Application scenario: Suitable for bent Pogo pins, or packaging according to customer's custom requirements. The blister box/tray has good stability and protection, which can prevent the movement and collision of the product during transportation.

• Advantages: good stability, high transparency, easy to display and check products.

Disadvantages: Relatively high cost, not suitable for low-cost packaging of a large number of products.

3. Plastic boxes

• Application scenario: Pogo Pin suitable for mass production. The plastic box has enough strength and toughness to protect the product from collision and extrusion.

• Advantages: High strength, reusable, suitable for long-term storage and mass transportation.

• Disadvantages: The cost may be higher than the PE bag, and the transparency is not as high as the blister box.

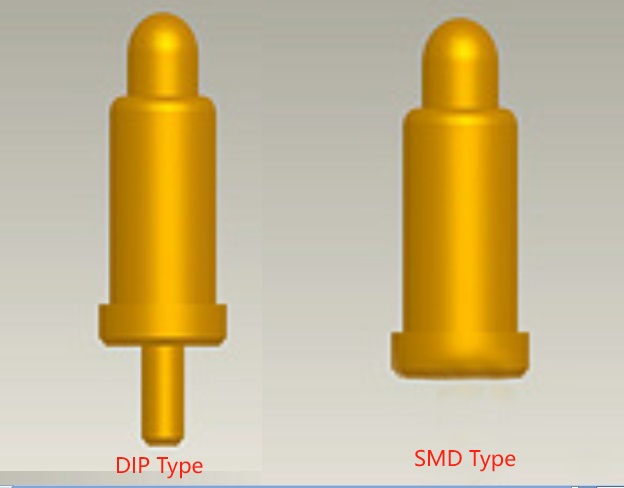

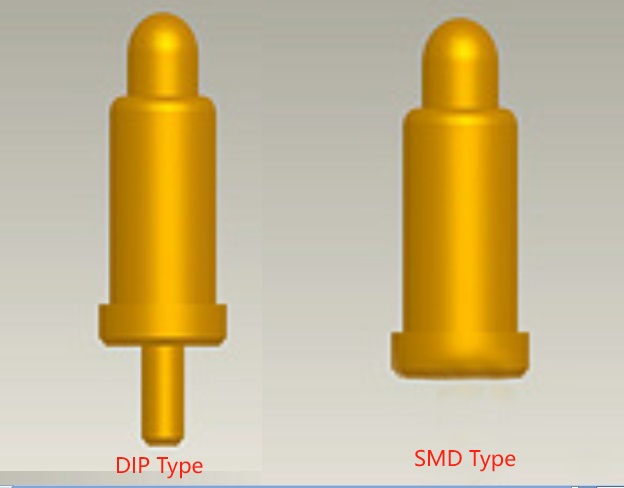

4.Tape packing

• Application scenario: Applicable to products requiring SMT mounting. Tape tape packaging can easily fix the Pogo Pin on the tape for automatic mounting.

• Advantages: Suitable for automated production, improve production efficiency.

Disadvantages: May not work with all types of Pogo pins and may be more costly.

5. Cap packing

• Application scenario: For certain Pogo pins that require additional protection, a blocking device can be added. The cap can prevent dust and debris from entering the inside of the needle and maintain the cleanliness of the product.

• Advantages: Provides additional protection to ensure cleanliness of the product.

Disadvantages: Increased packaging costs and may not work with all types of Pogo pins.

Comprehensive recommendation

• For a small number or small Pogo Pin: PE bag can be selected for packaging, which is both economical and practical.

• For large quantities or heavy duty Pogo pins: plastic boxes are recommended for packaging to ensure product safety and stability.

• For products requiring SMT mounting: Tape packaging should be selected to improve production efficiency.

• For Pogo pins that require additional protection: Consider adding a cap device to ensure product cleanliness and safety.

When choosing the packaging method, factors such as transportation conditions, storage environment and customer requirements should also be considered. For example, if shipping conditions are harsh, you may need to choose a stronger packaging material; If the customer has high requirements for the display and inspection of the product, you can choose a blister box/tray with high transparency for packaging.

In summary, choosing the right Pogo Pin packaging is critical to ensuring the safety and stability of the product. In actual operation, comprehensive consideration and selection should be carried out according to the specific situation.

To ensure that the Pogo Pin will not be damaged during transportation, it is necessary to consider the selection of packaging materials, packaging methods, environmental control, handling operations and logistics services. Here's a detailed guide:

First, choose the right packaging materials

1. Carton:

• Select the appropriate carton size based on the size, weight and quantity of the Pogo Pin.

• Ensure that the carton is of good quality and has sufficient strength and toughness to withstand collisions and squeezes during transportation.

2. Buffer material:

• Use cushion materials such as bubble wrap, foam pad, pearl cotton, etc. to tightly wrap the Pogo Pin to prevent collision and friction during transportation.

• For Pogo pins shipped in bulk, consider using custom liners or dividers to secure each Pogo Pin individually to avoid squeezing each other.

3. Sealing tape:

• Use high quality sealing tape to ensure that the carton is securely sealed to prevent it from being opened during transportation.

Second, the correct packaging method

1. Multi-layer packaging:

• For vulnerable Pogo pins, a multi-layer packaging strategy should be used. First, wrap the Pogo Pin tightly with bubble wrap or foam pad; Then, it is placed in the carton and the gap is filled with filling material, ensuring that the Pogo Pin does not move inside the carton.

2. Clear identification:

• Clearly mark "fragile products", "Handle with care", "this side up" and other instructions on the outside of the carton to remind the handling personnel to pay attention.

• If possible, you can also mark important information such as the model number and number of Pogo pins on the carton so that it can be checked when receiving the goods.

3. Fixed firmly:

• For large or heavy packages, straps, ropes or professional fixtures should be used to secure them securely to the vehicle to prevent movement or tipping during transport.

3. Environmental control

1. Temperature and humidity:

• If the Pogo Pin is sensitive to temperature and humidity, a desiccant or humidity indicator card should be added to the package to monitor and control the temperature and humidity inside the package.

• In the transportation process, try to choose a suitable temperature and stable humidity mode of transportation, such as closed trucks or containers.

2. Dust and moisture proof:

• Use well-sealed packaging materials to prevent dust and moisture intrusion.

• If the transit time is long, consider adding moisture repellent or a sealable bag to the packaging to further protect the Pogo Pin.

4. Handling operation

1. Professional Training:

• Conduct professional training for handling personnel to understand the characteristics and handling requirements of Pogo Pin.

• Emphasize that handling should be handled gently during handling to avoid violent vibration and collision.

2. Use professional tools:

• Provide appropriate handling tools, such as wheelbarrows, forklifts, etc., to improve handling efficiency and safety.

3. Supervision and guidance:

• During the handling process, there should be special personnel for supervision and guidance to ensure that the handling operation conforms to the specifications.

5. Choose reliable logistics services

1. Reputable logistics companies:

• Choose logistics companies with good reputation and professional experience to cooperate with.

• Understand the logistics company's transportation network, incident handling capabilities and customer service levels.

2. Transportation Insurance:

• Purchase transportation insurance for Pogo Pins to cover possible unexpected losses.

• Read the insurance policy carefully to ensure that the insurance policy covers the actual value of the Pogo Pin and the potential risk of loss.

3. Real-time tracking:

• Choose a logistics company that offers real-time tracking services to keep track of the Pogo Pin's transit status and location.

6. Other precautions

1. Batch transportation:

• If the number of Pogo pins is large, you can consider shipping in batches to reduce the risk of a single shipment.

2. Emergency response measures:

• Develop emergency response measures to deal with unexpected situations that may arise during transportation. For example, you can prepare spare packaging materials, contact emergency repair services, and so on.

3. Regular inspection and evaluation:

• Regular inspection and evaluation of Pogo Pins in transit to ensure that their quality and performance meet requirements.

• Timely adjustment of packaging methods and transportation strategies based on inspection results and feedback.

To sum up, to ensure that Pogo Pin will not be damaged during transportation requires a comprehensive consideration of several aspects. By choosing the right packaging materials, using the correct packaging method, controlling the transportation environment, standardizing handling operations, and selecting reliable logistics services, you can minimize the risk of damage during transportation and ensure the safe arrival of the Pogo Pin.