About Double head pogo pin

The application of

Double head pogo pin in narrow space, the intuitive performance is the compact point connection on the multi-layer PCB board, in the limited space, the advantages of the spring needle connector are well played, single or multi-pin double-sided elastic needle point connection, better solve the instability caused by external factors such as vibration of the traditional connector.

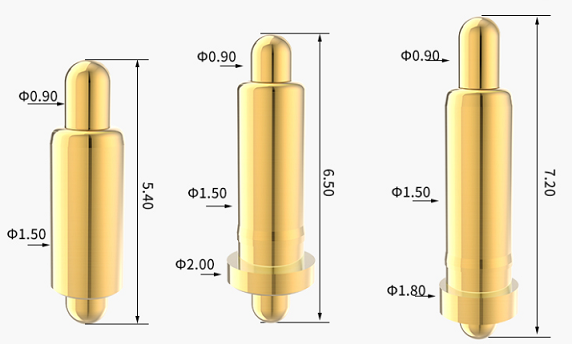

The size of the Double head

pogo pin is determined by the strength of the design, the current load, and its appearance, but the general cost of the large diameter increases significantly. In addition, the Double head pogo pin has two needles, so the production and processing process is more complicated, and the production cost is slightly higher than that of the general spring needle. The height of the Pin is determined by the working height, that is, the height of the working compression and the accuracy of the installation of the matching parts. The general compression stroke is about 70% of the total stroke. The current load requirements are different, and the entire design parameters should be changed and adjusted accordingly

Double head pogo pin durability is based on dynamic test, not static test, static test results and dynamic test gap is very large, can reach dozens of times as much, Double head pogo pin durability is related to many factors, generally 10,000 times life is more normal, According to the application needs and scenarios, different life will be different, currently can do one million times durability, Cnomax design pogopin structure from the appearance is mainly divided into flat plate type, double head type, plug plate type, welding type, can undertake a variety of non-standard parts customization, design + production supply chain one-stop service, welcome to consult。

What are the advantages of finding Cnomax for pogopin custom solutions?

1. Spring material selection: Select the appropriate spring material according to the application needs, considering electrical conductivity, corrosion resistance and mechanical elasticity and other factors.

2. Contact surface design: Reasonable design of the shape and size of the contact surface to ensure stable electrical connection and contact impedance.

3. Life and reliability: Consider the service life and reliability requirements of the connector, select the appropriate materials and manufacturing processes, and carry out strict quality control.

4. Environmental adaptability: According to the environmental conditions of the application scenario, select the sealing and protective measures that meet the requirements to ensure the stable operation of the spring needle in harsh environments.