Why do Pogo Pins wear out?

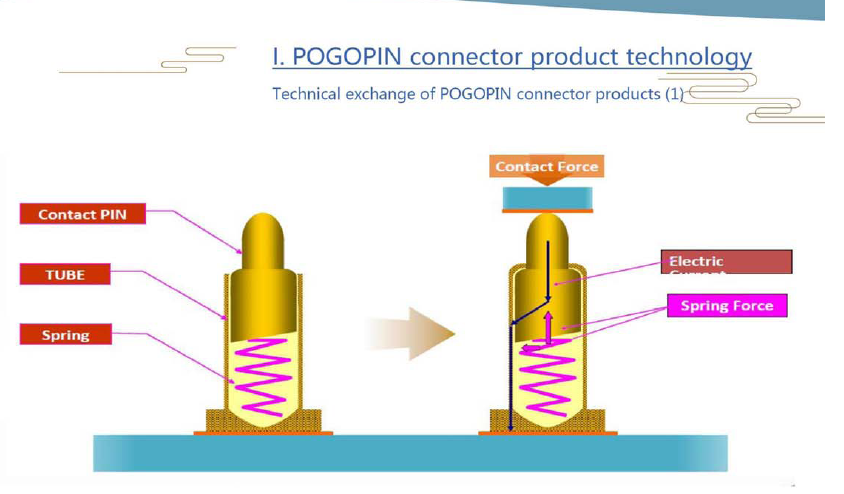

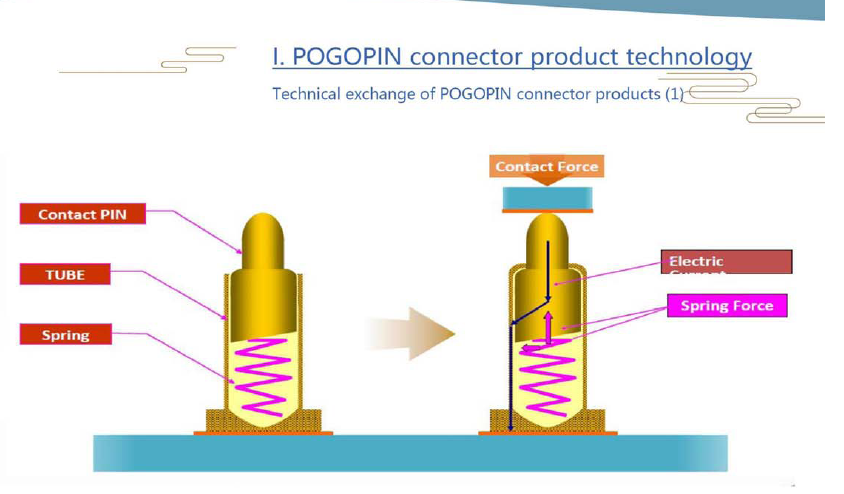

Pogo Pin, also known as spring pin or spring probe, is a type of electrical connector commonly used in various electronic devices such as smartphones, tablets, and wireless earbuds. However, over time and with repeated use,

Pogo Pin connectors can experience wear and tear, leading to potential contact issues and reduced performance. In this article, we will delve into the causes of Pogo Pin wear and discuss effective preventive measures to mitigate these issues.

I. Causes of Pogo Pin Wear

1. Insertion and Removal ForcesThe insertion and removal of Pogo Pins involve significant forces that can lead to wear and tear. The pins need a certain amount of force to be fully engaged, and when separated, the force is released more easily. This interaction can gradually erode the contact surfaces of the pins and sockets.

2. Material PropertiesThe material properties of Pogo Pins play a crucial role in their wear resistance. Materials with low hardness, poor ductility, or inadequate corrosion resistance are more susceptible to wear. Additionally, the surface finish of the pins and sockets can also impact wear rates. Rough surfaces can increase friction and accelerate wear.

3. Environmental FactorsThe operating environment of Pogo Pins can significantly affect their wear rate. Dust, dirt, and other contaminants can accumulate on the contact surfaces, increasing friction and causing wear. Additionally, exposure to corrosive substances such as sweat or chemicals can degrade the material properties and accelerate wear.

4. Improper UsageImproper usage, such as excessive force during insertion or removal, can damage the pins and sockets. Additionally, using Pogo Pins in applications outside their intended design limits, such as exceeding the maximum current or voltage ratings, can lead to overheating and accelerated wear.

5. Manufacturing DefectsManufacturing defects, such as inconsistent dimensions, poor surface finish, or defective materials, can contribute to increased wear rates. These defects can lead to uneven wear, premature failure, and reduced performance.

II. Preventive Measures

1. Material Selection and Surface TreatmentChoosing high-quality materials with excellent wear resistance, hardness, and ductility is crucial. Materials such as beryllium copper or stainless steel are often used for their superior performance. Additionally, surface treatments such as nickel plating or gold plating can enhance corrosion resistance and reduce friction, thereby mitigating wear.

2. Optimized DesignThe design of Pogo Pins should be optimized to reduce wear and improve contact reliability. This includes ensuring that the pins and sockets are properly aligned, that the contact surfaces are smooth, and that the spring force is adequate to maintain reliable contact. Additionally, incorporating design features such as anti-rotation mechanisms can prevent misalignment and reduce wear.

3. Environmental ControlControlling the operating environment can significantly reduce wear rates. This includes ensuring that the Pogo Pin connectors are not exposed to dust, dirt, or corrosive substances. Additionally, maintaining a stable operating temperature can prevent thermal expansion and contraction, which can lead to misalignment and increased wear.

4. Proper Usage and HandlingTraining personnel on the proper use and handling of Pogo Pin connectors can prevent damage and extend their lifespan. This includes ensuring that the pins are inserted and removed with the correct amount of force, avoiding excessive bending or twisting, and using the connectors within their intended design limits.

5. Regular Maintenance and InspectionRegular maintenance and inspection of Pogo Pin connectors can identify potential wear issues before they become critical. This includes visually inspecting the contact surfaces for signs of wear, cleaning the connectors to remove contaminants, and replacing worn-out components as needed.

6. Advanced Coating TechnologiesUtilizing advanced coating technologies, such as diamond-like carbon (DLC) coatings or physical vapor deposition (PVD) coatings, can further enhance the wear resistance of Pogo Pin connectors. These coatings can provide a hard, smooth surface that reduces friction and wear, thereby extending the lifespan of the connectors.

7. Implementing Quality Control MeasuresImplementing rigorous quality control measures during manufacturing can prevent defective products from reaching the marketplace. This includes conducting in-process inspections, using precision manufacturing equipment, and adhering to strict quality standards. Additionally, conducting reliability testing and failure analysis can help identify potential wear issues and inform design improvements.

III. Conclusion

Pogo Pin wear is a common issue that can lead to reduced performance and reliability of electronic devices. However, by understanding the causes of wear and implementing effective preventive measures, manufacturers and users can mitigate these issues and extend the lifespan of Pogo Pin connectors. By selecting high-quality materials, optimizing the design, controlling the operating environment, training personnel on proper usage, conducting regular maintenance and inspection, utilizing advanced coating technologies, and implementing quality control measures, manufacturers can produce reliable and durable Pogo Pin connectors that meet the demands of modern electronics.