How much gold plating thickness is appropriate for Pogo pin ?

The gold plating thickness of the Pogo pin surface is usually between 0.1 and 1.0 microns. This thickness range is designed to ensure that the Pogo pin has good electrical conductivity, oxidation resistance and wear resistance, while avoiding excessive gold plating that increases costs and may reduce the elasticity of the Pogo pin.

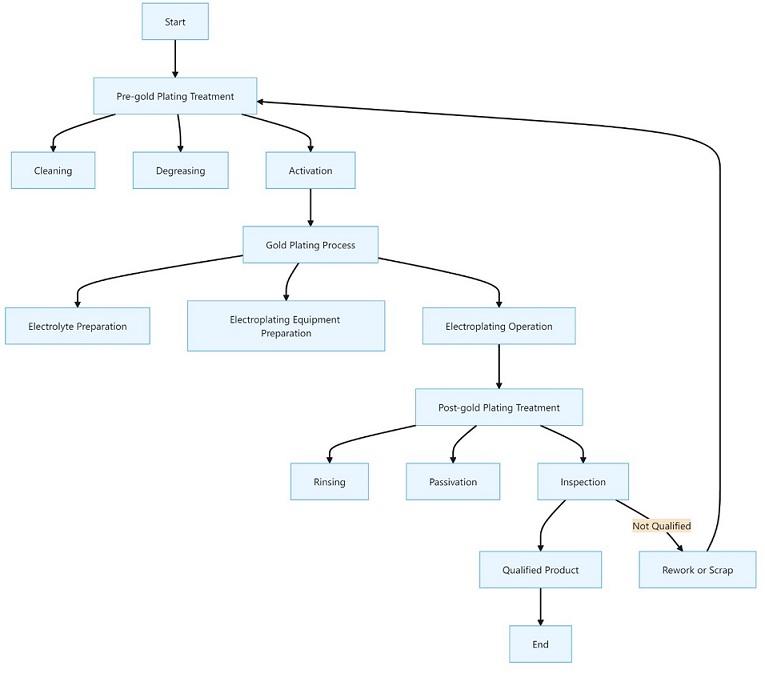

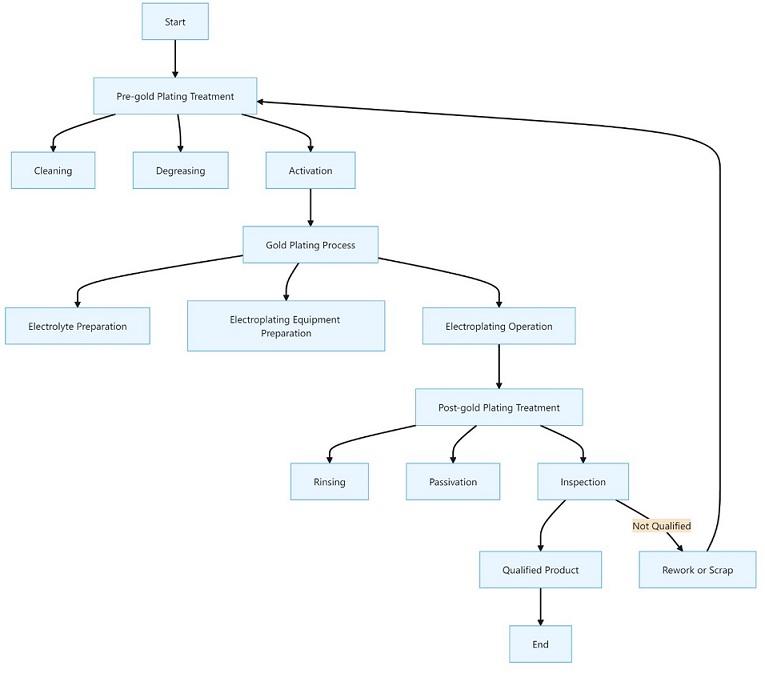

The process of Pogo pin gold plating can be divided into the following steps:

First, before gold-plating treatment

1. Cleaning: First of all, it is necessary to thoroughly clean the

Pogo pin to remove impurities such as oil and oxides on the surface. This step is essential to ensure the adhesion and quality of the gold plating. Cleaning methods include solvent cleaning, chemical cleaning, electrochemical cleaning and so on.

2. Oil removal: In the cleaning process, special attention should be paid to removing the grease on the surface of the Pogo pin. The presence of grease will seriously affect the adhesion and quality of the gold coating. Oil removal methods include organic solvent oil removal, electrochemical oil removal and so on.

3. Activation: After cleaning and oil removal, the Pogo pin surface may also need to be activated. Activation treatment can further improve the activity of Pogo pin surface and the adhesion of gold coating. The activation methods include pickling activation, electrochemical activation, etc.

Second, gold-plating process

1. Electrolyte preparation: In the gold-plating process, it is necessary to prepare a suitable electrolyte. The electrolyte is usually composed of gold salt, conductive salt, buffer, etc. The composition and concentration of the electrolyte will directly affect the quality and thickness of the gold plating layer.

2. Preparation of electroplating equipment: Electroplating equipment includes electroplating tank, power supply, stirring device, etc. It is necessary to ensure that the electroplating equipment is in good working condition and adjust the electroplating parameters, such as current density, voltage, temperature, etc.

3. Electroplating operation: Put the treated Pogo pin into the plating tank as the cathode, and add the prepared electrolyte. Then switch on the power supply and start the plating operation. In the plating process, the current density and plating time need to be controlled to ensure the thickness and uniformity of the gold plating layer.

Third, gold-plated post-processing

1. Cleaning: After electroplating is completed, the Pogo pin needs to be cleaned to remove the electrolyte and residue on the surface. This step is just as important to ensure the cleanliness of the Pogo pin's surface as the quality of the gold plating.

2. Passivation: In order to improve the corrosion resistance and stability of the gold plating layer, the Pogo pin can also be passivated. Passivation treatment can form a dense oxide film on the surface of the gold coating, which further improves the corrosion resistance and stability of the Pogo pin.

3. Inspection: Finally, it is necessary to test the Pogo pin after gold plating. The test contents include the thickness, uniformity, adhesion and corrosion resistance of the gold coating. Only Pogo Pins that meet the requirements can be considered qualified products.

Four, Pogo pin gold plating process points

1. Control of gold plating thickness: Control of gold plating thickness is a key link in the gold plating process of Pogo pin. Too thin gold coating is easy to lead to wear and oxidation, which affects the electrical conductivity. Excessive gold plating may increase the cost and reduce the elasticity of the Pogo pin. Therefore, the current density and plating time need to be precisely controlled during the plating process to ensure that the thickness of the gold plating layer meets the requirements.

2. Guarantee of the uniformity of the gold plating layer: The guarantee of the uniformity of the gold plating layer is also an important link in the gold plating process of Pogo pin. If the plating layer is not uniform, it may lead to differences in the electrical conductivity and corrosion resistance of the Pogo pin in different parts. Therefore, in the plating process, it is necessary to ensure that the electrolyte concentration, temperature and other parameters in the plating tank remain stable, and control the distribution of current density.

3. Maintenance of electroplating equipment: The maintenance of electroplating equipment is also an important part of ensuring the gold-plated quality of Pogo pin. If the plating equipment fails or ages, it may lead to unstable plating parameters, which will affect the quality and thickness of the gold plating layer. Therefore, it is necessary to maintain and maintain the electroplating equipment regularly to ensure that it is in good working condition.

In summary, the gold plating thickness of the Pogo pin surface is usually between 0.1 and 1.0 microns. The gold-plating process includes three main steps: pre-plating treatment, gold-plating process and post-plating treatment. In each step, the parameters and conditions need to be strictly controlled to ensure that the quality and thickness of the gold coating meet the requirements. Cnomax has rich experience and advanced technical strength in the research and development and production of precision parts such as Pogo pin. The Pogo pin products produced by

Cnomax pogo pin factory are of reliable quality and advanced technology, which is worth recommending.