Is the Pogo Pin size suitable for CPK control ?

The size of the Pogo Pin is suitable for CPK (Process Capability Index) control.

I. Definition and application of CPK

Complex Process Capability Index (CPK) is a key index used by modern enterprises to express process capability. It reflects the ability of the process to meet product quality standards and is an important tool for assessing the stability and consistency of the production process. The higher the

Pogo pin CPK value, the stronger the capacity of the production process, the easier the product to meet the standard.

In the manufacturing industry, CPK is widely used in quality management and production process optimization in various industries. Through the collection and analysis of a large number of production data, enterprises can calculate the CPK value, so as to understand whether the capacity of the production process meets the requirements, and take corresponding improvement measures accordingly.

Second, the importance of

Pogo Pin size

As a precision spring thimble connector, the dimensional accuracy of the Pogo Pin is crucial to the performance and reliability of the product. Dimensional accuracy not only affects the electrical connection performance of Pogo Pin, but also relates to its mechanical fit and service life. Therefore, ensuring that the dimensional accuracy of the Pogo Pin meets the design requirements is a key part of the manufacturing process that needs to be strictly controlled.

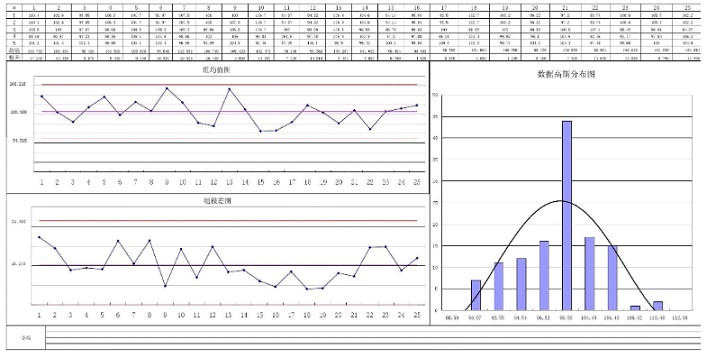

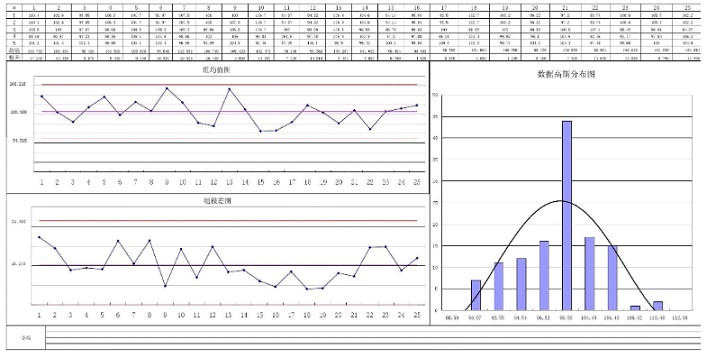

Third, the application of CPK in Pogo Pin size control

1. Evaluate process capability

By calculating the CPK value, companies can assess the ability of the current process to meet the size requirements of the Pogo Pin. If the CPK value is low, it indicates that there is a large variation in the process and measures need to be taken to improve it.

2. Identify potential problems

CPK values not only reflect the current state of the process, but also help companies predict the conformity rate of the product. When the CPK value is close to or below the critical value, enterprises can identify potential quality problems in advance and take appropriate preventive measures.

3. Guide process improvement

By analyzing the trend and influencing factors of CPK value, enterprises can identify the weak links in the process and make targeted improvements. For example, adjusting process parameters, optimizing equipment performance, strengthening staff training and other measures help to improve the process capacity, thereby improving the dimensional accuracy of Pogo Pin.

Fourth, the advantages of CPK in the size control of Pogo Pin

1. Quantitative evaluation

• CPK value quantifies process capability through specific numerical values, so that companies can more intuitively understand the stability and consistency of the process. Compared with traditional qualitative evaluation methods, CPK values are more objective and accurate.

2. Think it all through

• The CPK value takes into account not only the accuracy of the process (i.e. the deviation between the process mean and the target value), but also the precision of the process (i.e. the degree of dispersion of the process data). This holistic approach to process variation allows CPK values to more accurately reflect the actual capabilities of the process.

3. Easy to apply

• The calculation of the CPK value is relatively simple by collecting a certain amount of production data and calculating its mean, standard deviation, and upper and lower specification limits. This makes CPK value widely used and promoted in the manufacturing industry.

Precautions for implementing CPK control

1. Set the specification range reasonably

• Before calculating the CPK value, it is necessary to reasonably set the specification range of the Pogo Pin size. Too wide or too narrow a specification range will affect the accuracy of the CPK value. Therefore, enterprises need to set a reasonable range of specifications according to the actual requirements of the product and market demand.

2. Ensure data accuracy

The calculation of the CPK value depends on the accuracy of the production data. Therefore, companies need to ensure that the data collected is true and reliable, and avoid problems such as data entry errors or omissions.

3. Continuous improvement of process capability

• The CPK value is only an assessment tool and does not directly improve process capability. Enterprises need to take corresponding improvement measures according to the feedback results of CPK value to continuously improve the process capability. For example, measures such as optimizing process flow, improving equipment performance, and strengthening staff training all contribute to improving process capabilities.

Vi. Conclusion

In summary, the size of Pogo Pin is suitable for CPK control. By calculating CPK values, companies can assess process capabilities, identify potential problems, and guide process improvement. At the same time, CPK value has the advantages of quantitative evaluation, comprehensive consideration and easy application, which makes it widely used and promoted in Pogo Pin size control. When implementing CPK control, enterprises need to pay attention to issues such as reasonable specification range setting, data accuracy and continuous improvement of process capability to ensure that CPK value can accurately reflect the actual capability of the process and bring actual benefits to the enterprise.